What Is A Solar Charge Controller?

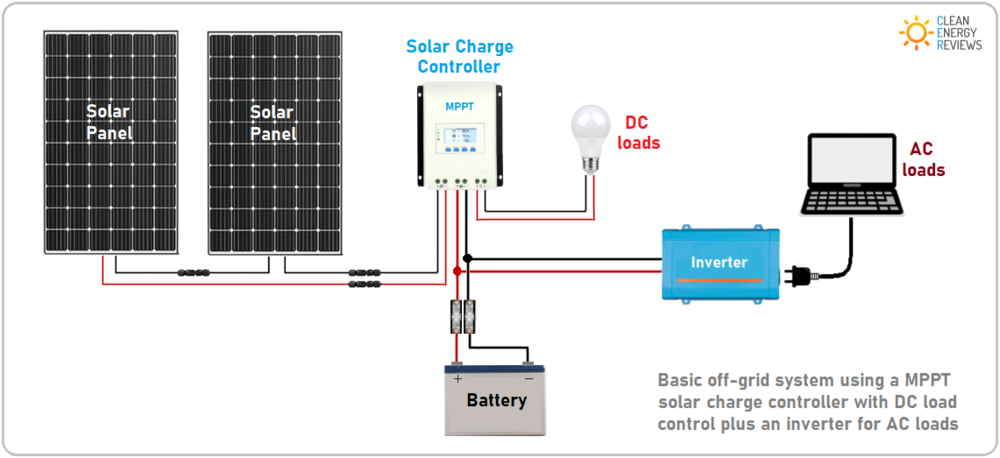

A solar charge controller, also known as a solar regulator, is basically a solar battery charger connected between the solar panels and battery. Its job is to regulate the battery charging process and ensure the battery is charged correctly, or more importantly, not over-charged. DC-coupled solar charge controllers have been around for decades and are used in almost all small-scale off-grid solar power systems.

Charge control devices controls the energy coming from solar panels. It adjusts the current and the voltage then send it to batteries. Charge control device prevents over charge and over discharge of the batteries. Therefore, it protects the system. Each solar energy systems requires a charge control device. Charge control devices divided into two as PWM (Pulse Width Modulation) and MPPT (Maximum Power Point Tracking)

Modern solar charge controllers have advanced features to ensure the battery system is charged precisely and efficiently, plus features like DC load output used for lighting. Generally, most smaller 12V-24V charge controllers up to 30A have DC load terminals and are used for caravans, RVs and small buildings. On the other hand, most larger, more advanced 60A+ MPPT solar charge controllers do not have load output terminals and are specifically designed for large off-grid power systems with solar arrays and powerful off-grid inverter-chargers.

Solar charge controllers are rated according to the maximum input voltage (V) and maximum charge current (A). As explained in more detail below, these two ratings determine how many solar panels can be connected to the charge controller.

-

Current Amp (A) rating = Maximum charging current.

-

Voltage (V) rating = Maximum voltage (Voc) of the solar panel/s.

MPPT Vs PWM Solar Charge Controllers

There are two main types of solar charge controllers, PWM and MPPT, with the latter being the primary focus of this article due to the increased charging efficiency, improved performance and other advantages explained below.

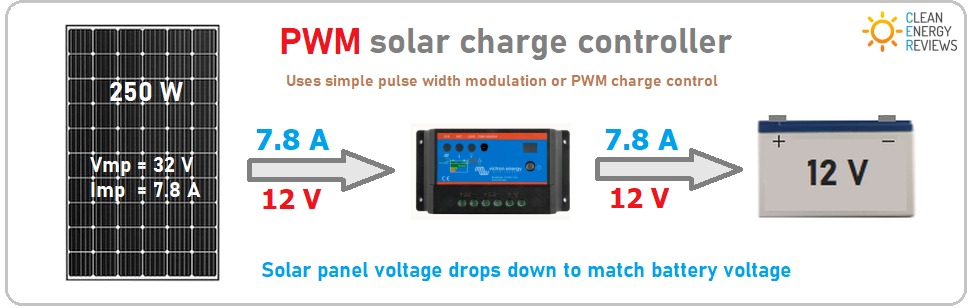

PWM Solar Charge Controllers

Simple PWM, or ‘pulse width modulation’ solar charge controllers have a direct connection from the solar array to the battery and use a basic ‘rapid switch’ to modulate or control the battery charging. The switch (transistor) is open until the battery reaches the absorption charge voltage. Then the switch starts to open and close rapidly (hundreds of time per second) to modulate the current and maintain a constant battery voltage. This works ok, but the problem is the solar panel voltage is pulled down to match the battery voltage. This in turn pulls the panel voltage away from its optimum operating voltage (Vmp) and reduces the panel power output and operating efficiency.

PWM solar charge controllers are a great low-cost option for small 12V systems when one or two solar panels are used, such as simple applications like solar lighting, camping and basic things like USB/phone chargers. Note, if more than one panel is used, they should be connected in parallel, not series.

MPPT Solar Charge Controllers

MPPT stands for Maximum Power Point Tracker; these are far more advanced than PWM charge controllers and enable the solar panel to operate at its maximum power point, or to be more precise, the optimum voltage and current for maximum power output. Using this clever technology, MPPT solar charge controllers can be up to 30% more efficient, depending on the battery voltage and operating voltage (Vmp) of the solar panel. The reasons for the increased efficiency and how to correctly size an MPPT charge controller are explained in detail below.

As a general guide, MPPT charge controllers should be used on all higher power systems using two or more solar panels or whenever the panel voltage (Vmp) is 8V or higher than the battery voltage – see full explanation below.

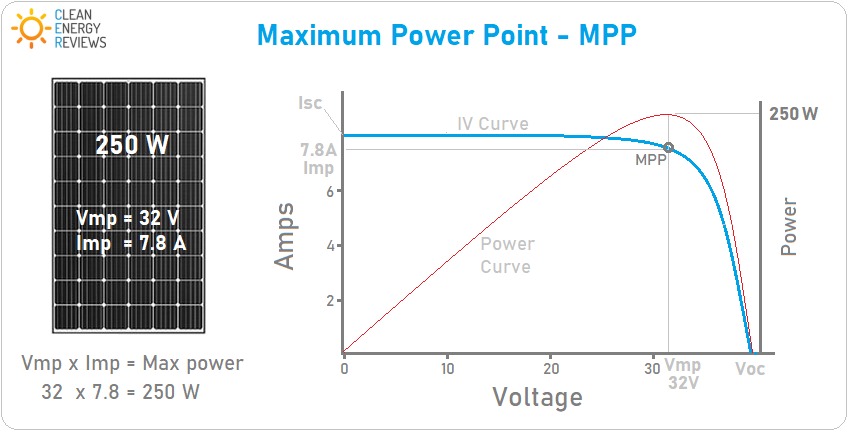

What Is An MPPT Or Maximum Power Point Tracker?

A maximum power point tracker, or MPPT, is basically an efficient DC to DC converter used to maximise the power output of a solar system. The first MPPT was invented by a small Australian company called AERL way back in 1985, and this technology is now used in virtually all grid-connect solar inverters and all MPPT solar charge controllers.

The functioning principle of an MPPT solar charge controller is rather simple – due to the varying amount of sunlight (irradiance) landing on a solar panel throughout the day, the panel voltage and current continuously vary. In order to generate the most power, an MPPT sweeps through the panel voltage to find the sweet spot or the best combination of voltage and current to produce the maximum power. The MPPT continually tracks and adjusts the PV voltage to generate the most power, no matter what time of day or weather conditions. Using this clever technology, the operating efficiency greatly increases and the energy generated can be up to 30% more compared to a PWM charge controller.

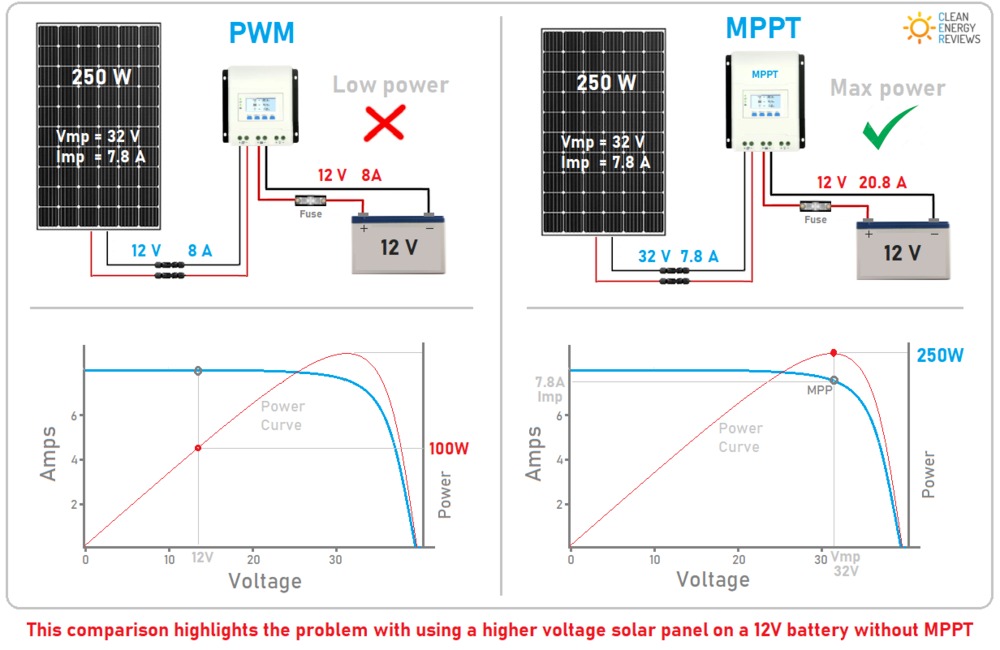

PWM Vs MPPT Example

In the example below, a common 60 cell (24V) solar panel with an operating voltage of 32V (Vmp) is connected to a 12V battery bank using both a PWM and an MPPT charge controller. Using the PWM controller, the panel voltage must drop to match the battery voltage and so the power output is reduced dramatically. With an MPPT charge controller, the panel can operate at its maximum power point and in turn can generate much more power.

PWM stands for Pulse Width Modulation. PWM charge control devices can be explained as an electrical switch between batteries. The switch can be quickly switch on and switch off. Therefore, desired voltage can be obtained to charge the batteries. The charge current will be slowly decreased as the batteries charged.

MPPT stands for Maximum Power Point Tracking. MPPT is a technique to observe and regulates the energy going from solar panel to the batteries. Solar panels show changeable outputs according to weather conditions. MPPT charge control devices can match the solar panel voltage with battery voltage to maximize the charge efficiency. In these systems, the full power of solar panels can be used by balancing between voltage and current according to the P = V x A equation. For example, the amount of current drawn from the panels reduced to protect the voltage when the weather is cloudy. When the weather is sunny, it is allowed to draw more current.

The main difference between PWM and MPPT charge control devices is that the MPPT devices are more efficient. MPPT charge control devices have 30 % more efficient in charge efficiency according to PWM type. Panel voltage and battery voltage should be matched in PWM systems. In MPPT systems, the panel series are allowed to have higher voltage than batteries. This means more flexibility for system growth.

On the other hand, MPPT controllers are more expensive than PWM controllers. Because of that, in small systems where the efficiency is not critical, are still using PWM charge controller.

The size of the solar energy system is important to choose charge control device. MPPT charge control devices are the best for professional applications. PWM charge regulators can provide sufficient performance in small applications which does not need more property. The efficiency difference between PWM and MPPT may not be sufficient to justify the price difference in small projects. However, in big projects, it plays a huge role about how well the system performance.

Battery Voltage Options

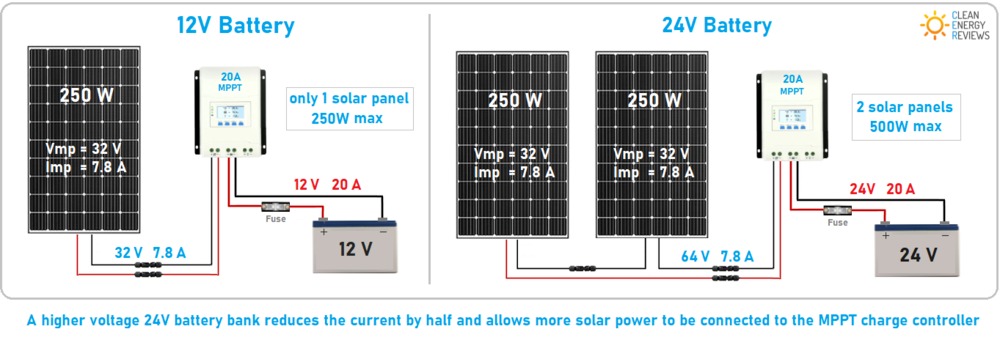

Unlike battery inverters, most MPPT solar charge controllers can be used with a range of different battery voltages. For example, most smaller 10A to 30A charge controllers can be used to charge either a 12V or 24V battery, while most larger capacity, or higher input voltage charge controllers, are designed to be used on 24V or 48V battery systems. A select few, such as the Victron 150V range, can even be used on all battery voltages from 12V to 48V. There are also several high voltage solar charge controllers, such as those from AERL and IMARK which can be used on 120V battery banks.

Besides the current (A) rating, the maximum solar array size that can be connected to a solar charge controller is also limited by the battery voltage. As highlighted in the following diagram, using a 24V battery enables much more solar power to be connected to a 20A solar charge controller compared to a 12V battery.

The diagram above shows how a higher 24V battery enables more solar panels to be connected using the same 20A solar charge controller. Click to enlarge

Based on Ohm’s law and the power equation, higher battery voltages enable more solar panels to be connected. This is due to the simple formula – Power = Voltage x Current (P=V*I). For example 20A x 12.5V = 250W, while 20A x 25V = 500W. Therefore, using a 20A controller with a higher 24V volt battery, as opposed to a 12V battery, will allow double the amount of solar to be connected.

-

20A MPPT with a 12V battery = 260W max Solar recommended

-

20A MPPT with a 24V battery = 520W max Solar recommended

-

20A MPPT with a 48V battery = 1040W max Solar recommended

Note, oversizing the solar array is allowed by some manufacturers to ensure an MPPT solar charge controller operates at the maximum output charge current, provided the maximum input voltage and current are not exceeded! See more in the oversizing solar section below.

Solar Panel Voltage Vs Battery Voltage

For an MPPT charge controller to work correctly, the solar panel operating voltage must be at least 4V to 5V higher than the battery charging (absorption) voltage, not the nominal battery voltage. On average, the real-world panel operating voltage is around 3V lower than the optimum panel voltage (Vmp).

All solar panels have two voltage ratings which are determined under standard test conditions (STC) based on a cell temperature of 25°C. The first is the maximum power voltage (Vmp) which drops slightly under cloudy conditions or more so when the solar panel temperature increases. The second is the open-circuit voltage (Voc) which also decreases at higher temperatures. In order for the MPPT to function correctly, the panel operating voltage (Vmp) must always be several volts higher than the battery charge voltage under all conditions, including high temperatures – see more detail about voltage drop and temperature below.

12V Batteries

In the case of 12V batteries, the panel voltage drop due to high temperature is not a big problem as most (12V) solar panels operate in the 18V to 22V range, which is much higher than the typical 12V battery charge (absorption) voltage of 14.4V. Also, common 60-cell (24V) solar panels are not a problem as they operate in the 30V to 40V range which is much higher.

24V Batteries

In the case of 24V batteries, there is no issue when 2 or more solar panels are connected in series, but there is a problem when only 1 solar panel is connected. Most common (24V) 60-cell solar panels have a Vmp of 32V to 36V – While this is higher than the battery charging voltage of around 28V, the problem occurs on a hot day when the panel temperature increases and the panel voltage can drop by up to 6V. This large voltage drop can result in the solar voltage dropping below the battery charge voltage, thus preventing it from fully charging. A way to get around this when using only one panel is to use a larger, higher voltage 72-cell or 96-cell panel.

48V Batteries

When charging 48V batteries, the system will need at least 2 panels in series but will perform much better with 3 or more panels in series, depending on the maximum voltage of the charge controller. Since most 48V solar charge controllers have a max voltage (Voc) of 150V, this generally allows up to 3 panels to be connected in series. The higher voltage 250V charge controllers can have strings of 5 or more panels which is much more efficient on larger solar arrays as it reduces the number of strings in parallel and in turn lowers the current.

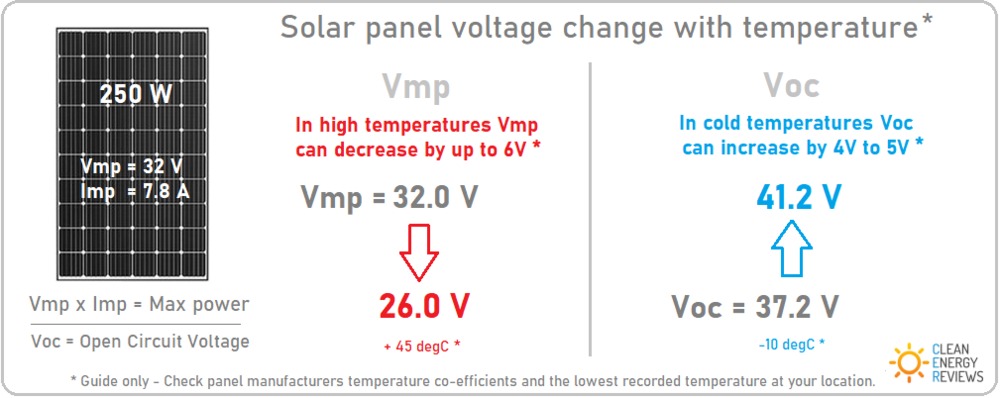

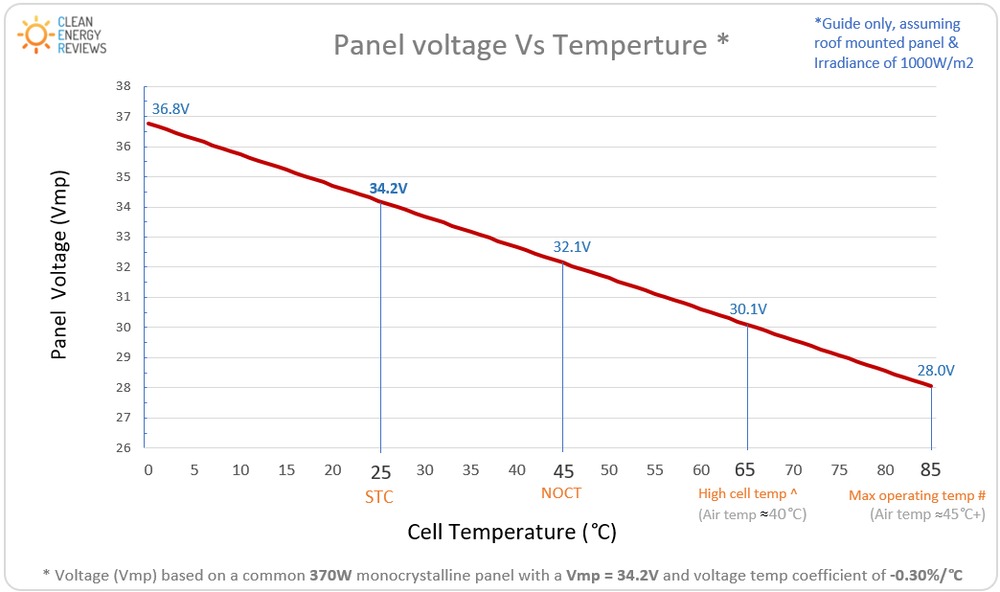

Solar Panel Voltage Vs Temperature

The power output of a solar panel can vary significantly depending on the temperature and weather conditions. A solar panel’s power rating (W) is measured under Standard Test Conditions (STC) at a cell temperature of 25°C and an irradiance level of 1000W/m2. However, during sunny weather, solar panels slowly heat up, and the internal cell temperature will generally increase by at least 20°C above the ambient air temperature; this results in increased internal resistance and a reduced voltage (Vmp). The amount of voltage drop is calculated using the voltage temperature co-efficient listed on the solar panel datasheet.

Both the Vmp and Voc of a solar panel will decrease during hot sunny weather as the cell temperature increases. During very hot days, with little wind to disperse heat, the panel temperature can rise as high as 80°C when mounted on a dark-coloured rooftop. On the other hand, in cold weather, the operating voltage of the solar panel can increase significantly, up to 5V or even higher in freezing temperatures. Voltage rise must be taken into account as it could result in the Voc of the solar array going above the maximum voltage limit of the solar charge controller and damaging the unit.

Panel Voltage Vs Cell Temperature graph notes:

-

STC = Standard test conditions – 25°C (77°F)

-

NOCT = Nominal operating cell temperature – 45°C (113°F)

-

(^) High cell temp = Typical cell temperature during hot summer weather – 65°C (149°F)

-

(#) Maximum operating temp = Maximum panel operating temperature during extremely high temperatures mounted on a dark rooftop – 85°C (185°F)

Voltage increase in cold weather

Example: A Victron 100V/50A solar charge controller has a maximum solar open-circuit voltage (Voc) of 100V, and a maximum charging current of 50 Amps. If you use 2 x 300W solar panels with 46 Voc in series, then you have a maximum of 92V. This seems ok, as it is below the 100V maximum. However, in extremely cold conditions the panel voltage will go much higher than the Voc. This is calculated using the voltage temperature co-efficient of the solar panel, which is typically 0.3% for every degree below STC – 25°C cell temperature. However, to simplify things, you can generally add 5V to the panel Voc (for temperatures down to -10°C **). In this case, you would end up with a Voc of 102V. This is now greater than the max 100V input voltage limit and could damage the MPPT or void your warranty.

Solution: There are two ways to get around this issue:

-

Select a different MPPT solar charge controller with a higher input voltage rating such as the Victron 150V/45A.

-

Connect the panels in parallel instead of series. The maximum voltage will now be 46V + 5V = 51 Voc. Note, this will only work if you are using a 12V or 24V battery system, but it’s not suitable for a 48V system as the voltage is too low. Also note, in parallel the solar input current will double so the solar cable should be rated accordingly.

Note: Assuming you are using a 12V battery and 2 x 300W panels, the MPPT charger controller output current will be roughly: 600W / 12V = 50A max. So you should use a 50A MPPT solar charge controller.

** Guide only – check the lowest recorded temperature at your location.

Sizing A Solar Charge Controller

Basic Guide

The charge controller Amp (A) rating should be 10 to 20% of the battery Amp/hour (Ah) rating. For example, a 100Ah 12V lead-acid battery will need a 10A to 20A solar charge controller. A 150W to 200W solar panel will be able to generate the 10A* charge current needed for a 100Ah battery to reach the adsorption charge voltage provided it is orientated correctly and not shaded. *Note: Always refer to the battery manufacturer’s specifications.

Advanced Guide To Off-Grid Solar Systems

Before selecting an MPPT solar charge controller and purchasing panels, batteries or inverters, you should understand the basics of sizing an off-grid solar power system. The general steps are as follows:

-

Estimate the loads – how much energy you use per day in Ah or Wh

-

Battery capacity – determine the battery size needed in Ah or Wh

-

Solar size – determine how many solar panel/s you need to charge the battery (W)

-

Choose the MPPT Solar Charge Controller/s to suit the system (A)

-

Choose an appropriately sized inverter to suit the load.

1. Estimate the loads

The first step is to determine what loads or appliances you will be running and for how long? This is calculated by – the power rating of the appliance (W) multiplied by the average runtime (hr). Alternatively, use the average current draw (A) multiplied by average runtime (hr).

-

Energy required in Watt hours (Wh) = Power (W) x Time (hrs)

-

Energy required in Amp hours (Ah) = Amps (A) x Time (hrs)

Once this is calculated for each appliance or device, then the total energy requirement per day can be determined as shown in the attached load table.

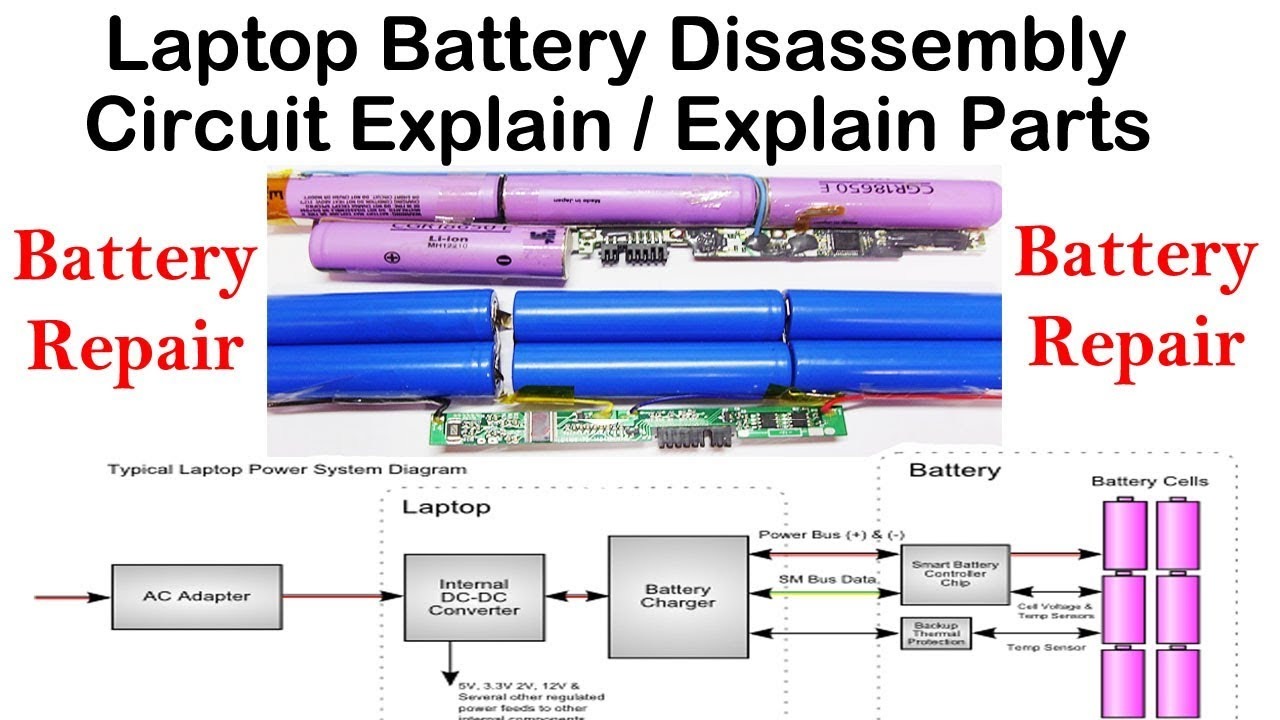

2. Sizing the Battery

The total load in Ah or Wh load is used to size the battery. Lead-acid batteries are sized in Ah while lithium batteries are sized in either Wh or Ah. The allowable daily depth of discharge (DOD) is very different for lead-acid and lithium, see more details about lead-acid Vs lithium batteries. In general, lead-acid batteries should not be discharged below 70% SoC (State of Charge) on a daily basis, while Lithium (LFP) batteries can be discharged down to 20% SoC on a daily basis. Note: Lead-acid (AGM or GEL) batteries can be deeply discharged, but this will severely reduce the life of the battery if done regularly.

For example: If you have a 30Ah daily load, you will need a minimum 100Ah lead-acid battery or a 40Ah lithium battery. However, taking into account poor weather, you will generally require at least two days of autonomy – so this equates to a 200Ah lead-acid battery or an 80Ah lithium. Depending on your application, location, and time of year, you may even require 3 or 4 days of autonomy.

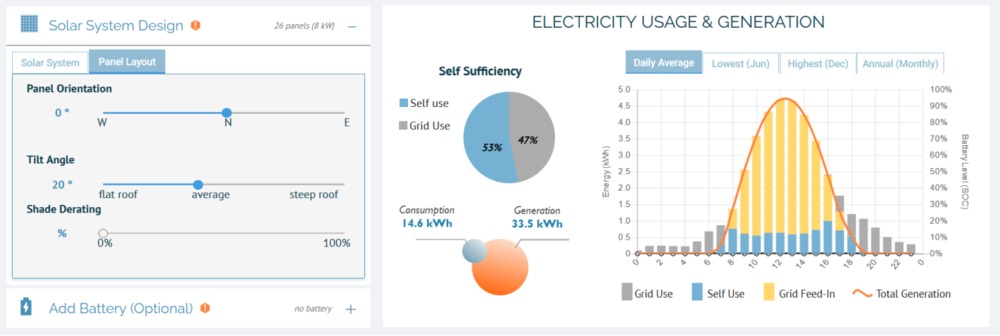

3. Sizing the Solar

The solar size (W) should be large enough to fully charge the battery on a typical sunny day in your location. There are many variables to consider including panel orientation, time of year & shading issues. This is actually quite complex, but one way to simplify things it to roughly work out how many watts are required to produce 20% of the battery capacity in Amps. Oversizing the solar array is also allowed by some manufacturers to help overcome some of the losses. Note that you can use our free solar design calculator to help estimate the solar generation for different solar panel tilt angles and orientations.

Solar sizing Example: Based on the 20% rule, A 12V, 200Ah battery will need up to 40Amps of charge. If we are using a common 250W solar panel, then we can do a basic voltage and current conversion:

Using the equation (P/V = I) then 250W / 12V battery = 20.8A

In this case, to achieve a 40A charge we would need at least 2 x 250W panels. Remember there are several loss factors to take into account so slightly oversizing the solar is a common practice – See more about oversizing solar below.

4. Solar Charge controller Sizing (A)

The MPPT solar charge controller size should be roughly matched to the solar size. A simple way to work this out is using the power formula:

Power (W) = Voltage x Current or (P = V*I)

If we know the total solar power in watts (W) and the battery voltage (V), then to work out the maximum current (I) in Amps we re-arrange this to work out the current – so we use the rearranged formula:

Current (A) = Power (W) / Voltage or (I = P/V)

For example: if we have 2 x 200W solar panels and a 12V battery, then the maximum current = 400W/12V = 33Amps. In this example, we could use either a 30A or 35A MPPT solar charge controller.

5. Selecting a battery inverter

Battery inverters are available in a wide range of sizes determined by the inverter’s continuous power rating measured in kW (or kVA). More importantly, inverters are designed to operate with only one battery voltage which is typically 12V, 24V or 48V. Note that you cannot use a 24V inverter with a lower 12V or higher 48V battery system. Pro-tip, it’s more efficient to use a higher battery voltage.

Besides the battery voltage, the next key criteria for selecting a battery inverter are the average continuous AC load (demand) and short-duration peak loads. Due to temperature de-rating in hot environments, the inverter should be sized slightly higher than the load or power demand of the appliances it will be powering. Whether the loads are inductive or resistive is also very important and must be taken into account. Resistive loads such as electric kettles or toasters are very simple to power, while inductive loads like water pumps and compressors put more stress on the inverter. In regards to peak loads, most battery inverters can handle surge loads up to 2 x the continuous rating.

Inverter sizing example:

-

Average continuous loads = 120W (fridge) + 40W (lights) + TV (150W) = 310W

-

High or surge loads = 2200W (electric kettle) + toaster (800W) = 3000W

Considering the above loads, a 2400W inverter (with 4800 peak output) would be adequate for the smaller continuous loads and easily power the short-duration peak loads.

MPPT Solar Oversizing

Due to the various losses in a solar system, it is common practice to oversize the solar array to enable the system to generate more power during bad weather and under different conditions such as high temperatures where power derating can occur. The main loss factors include – poor weather (low irradiation), dust and dirt, shading, poor orientation, and cell temperature de-rating (refer to the power temperature co-efficient on the solar panel spec sheet for more details). Learn more about solar panel efficiency and cell temperature de-rating.

These various loss factors listed above can add up as high as 20%. For example, a 300W solar panel will generally produce 240W to 270W in summer due to the temperature power de-rating, and in winter or due to lower irradiance levels, depending on your location. For these reasons, oversizing the solar array beyond the manufacturers ‘recommended or nominal value’ will help to generate more power. Oversizing by 150% or more is possible on some professional MPPT solar charge controllers. However, not all solar charge controllers are designed to handle the excess power when the solar is operating at full capacity and this can damage some controllers. Therefore, it is important to always check the manufacturer allows oversizing – Morningstar and Victron both allow oversizing beyond the nominal values listed on the datasheets but always double-check the manufacturer’s specifications.

Warning – you must NEVER exceed the maximum INPUT voltage (Voc) or maximum input current rating of the solar charge controller!