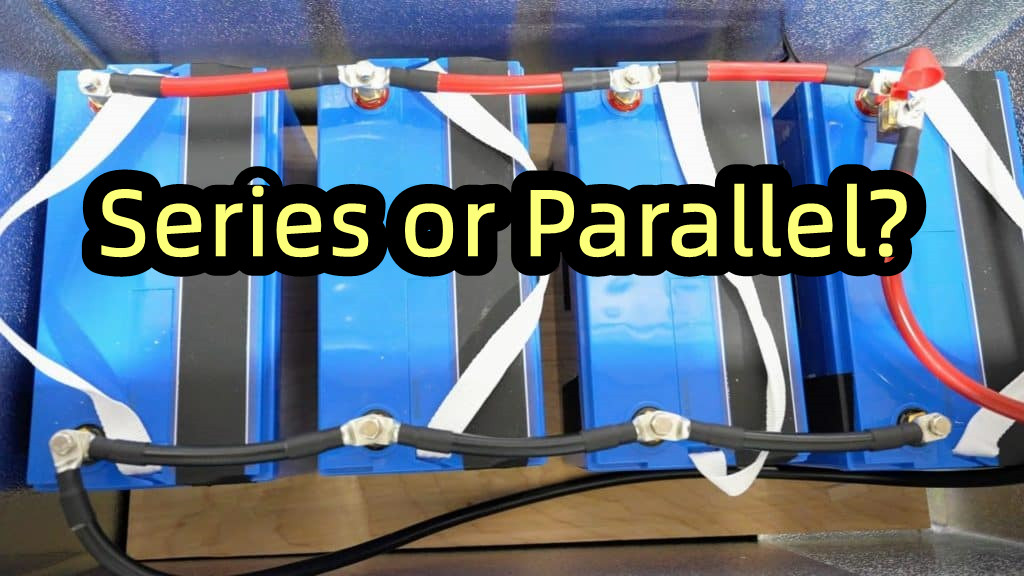

Battery Series/parallel Connection

Types of Battery Connections

There are three basic types of batteries connection.

1.)Series Connection

2.)Parallel Connection

3.)Series-Parallel Connection

What is lithium battery in series?

If we connect the positive (+) terminal of battery to negative (-) and negative to positive terminal as shown in the below fig, then the batteries configuration would be in series.

Features of Lithium Battery in Series Connction:

- the voltage is added

- the current is the same

- the capacity remains the same

- the internal resistance increases

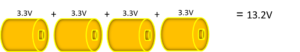

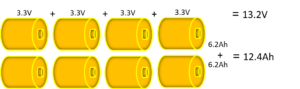

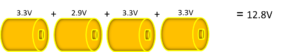

Vs=V1+V2+V3+…….+Vn

I1=I2=I3=….=In

C1=C2=C3=….=Cn

R=R1+R2+R3+R4+……+Rn

Series voltage: 3.7V single batteries can be assembled into battery packs with a voltage of 3.7*(N)V as needed (N: number of single batteries) such as 7.4V, 12V, 24V, 36V, 48V, 60V, 72V, ETC.

Battery packs are designed by connecting multiple cells in series; each cell adds its voltage to the battery’s terminal voltage.

battery connect in series

Do not let lithium batteries with different voltages in series.

Due to the problem of consistency of lithium batteries, they are grouped in series under the same system (such as ternary or lithium iron), and they also need to be selected with the same voltage, internal resistance, and capacity. Batteries with different voltage platforms and different internal resistance are used in series, which will cause a battery to be fully charged and discharged first in each cycle. If there is a protection board and there is no failure, it will cause the capacity of the entire set to be reduced. Without a protection board, it is bound to cause the battery to be overcharged or overcharged and cause damage.

When we neeed to connect batteries in series?

If you need to double the voltage level according to your system needs while maintain the same capacity or ampere hour (Ah) rating of batteries.

For example, If you have two 12V, 10Ah hour batteries and you need 48V system for installation.

Simply, connect four batteries in series where you will get 48V and the same ampere hour rating i.e. 10Ah.

What you need to keep in mind is that battery discharge slowly in series connection as compared to parallel batteries connection. You can do it with any number of batteries i.e. to get 24V, 36V, 48V, 72V DC and so on by connecting batteries in series.

Batteries may consist of combination of series and parallel connections. Cells in parallel increased current handling; each cell adds to the ampere-hour (Ah) total of the battery

A weaker cell in series connected cells would cause an imbalance. This is especially critical in a series configuration because a battery is only as strong as the weakest cell (analogous to the weak link in the chain). A weak cell may not fail immediately but may be drained (voltage dropping below a safe level, 2.8V per cell) more quickly than the strong ones when discharging. On charge, the weak cell may fill up before the healthy ones and be over-charged (voltage exceeding 3.9V per cell). Unlike the weak link in a chain analogy, a weak cell causes stress on the other healthy cells in a battery. Cells in multi-packs must be matched, especially when exposed to high charge and discharge currents.

Charging Lithium Battery in Series

At present, the charging of lithium battery packs generally adopts series charging, mainly because the series charging method has a simple structure, low cost and easier to implement

However, due to the differences in capacity, internal resistance, attenuation characteristics, self-discharge and other properties between single lithium batteries,when charging the lithium battery pack in series, the single lithium battery with the smallest capacity in the battery pack will be the first to be fully charged.

At this time, other batteries have not been fully charged. If you continue to charge in series, the fully charged single lithium battery may be overcharged. Overcharging lithium batteries can seriously damage the performance of the battery, and may even cause explosions and cause injuries. Therefore,in order to prevent overcharging of single lithium batteries, lithium battery packs are generally equipped with a battery management system (BMS) when used, which protects each single lithium battery from overcharging through the battery management system. When charging in series, if the voltage of a single lithium battery reaches the overcharge protection voltage, the battery management system will cut off the entire series charging circuit and stop charging to prevent the single battery from being overcharged, which will cause other lithium batteries to be unable to be fully charged.

Do not let lithium batteries with different capacities in parallel.

If different capacities or old and new lithium batteries are mixed together, there may be leakage, zero voltage and other phenomena. This is due to the difference in capacity during the charging process. Some batteries are overcharged when charging, and some batteries are not fully charged. When discharging, there are high-capacity batteries that are not fully charged, while those with low capacity are overcharged. In such a vicious circle, the battery is damaged and leaks liquid or low (zero) voltage.

Do not let lithium batteries in parallel if their materials are different

There is a charging and discharging process of the battery. Even if the voltage of the battery of different materials is exactly the same in the initial state, the battery cannot be connected in parallel. With different battery materials, the energy density ratio is different, and the discharge characteristic curve is inconsistent when discharging, which will cause the voltage of the two batteries to be inconsistent. At this time, a battery with a high voltage may charge a battery with a low voltage, causing serious heat generation.;

When charging, due to the inconsistency of the remaining charge, the charging speed will inevitably lead to inconsistency. If the battery is fully charged, there will be overshoot, which will also cause problems with the battery, and it will catch fire or even explode in severe cases. Therefore, batteries of different materials must not be connected in parallel.

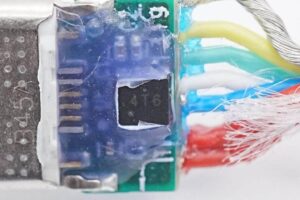

Battery Management System (BMS) Cell Protection

A BMS continuously monitors each cell’s voltage. If the voltage of a cell exceeds the others, the BMS circuits will work to reduce that cell’s charge level. This ensures that the charge level of all the cells remains equal, even with the high discharge (> 100Amps) and charge current (>10Amps).

A cell can be permanently damaged if over-charged (over-voltage) or over-discharged (drained) just one time. The BMS has circuitry to block charging if the voltage exceeds 15.5 volts (or if any cell’s voltage exceeds 3.9V). The BMS also disconnects the battery from the load if it is drained to less than 5% remaining charge (an over-discharge condition). An over-discharged battery typically has a voltage less than 11.5V (< 2.8V per cell).

These Aspects you need to mind when you charge Lithium Battery in Parallel

1.) One Lithium battery with protection plates and one lithium battery without protection plates cannot be charged in parallel. Batteries without protective plates are easily damaged by overcharging.

2.) Batteries that are charged in parallel usually need to remove the protection board that comes with the battery and use a unified battery protection board.

3.) If the battery charged in parallel does not have a lithium battery protection board, the charging voltage must be limited to 4.2V, and a 5V charger cannot be used.

4.) After the lithium batteries are connected in parallel, there will be a charging protection chip to charge and protect the lithium batteries. When making parallel lithium batteries, lithium battery manufacturers have fully considered the characteristics of the changes after the lithium batteries are connected in parallel, and the current design and battery selection are also carried out in accordance with the above requirements. Therefore, users need to follow the instructions for parallel lithium batteries to charge step by step to avoid damage that incorrect charging may cause to the battery.

When We Need to Connect Batteries in Series-Parallel?

When you need to double the battery capacity or ampere hours (Ah) rating as well as batteries voltages according to your system needs.

For example, If you have six batteries each of 12V, 200Ah hour and you need 600Ah capacity and 24V system for installation. Now you have two sets of three batteries, simply, connect two sets of three batteries in series and then connect the two set in parallel (as shown in fig above) where the overall battery capacity would be 600Ah and level of voltages would be 24V.

You can do it with any number of batteries i.e. to get different level of voltages as well as increase the battery capacity in ampere hours in series-parallel connection of batteries.

Should lithium battery packs be in series first? or in parallel first?

The advantages of lithium batteries in parallel and then in series

- ) The failure of the lithium battery cell automatically exits, except for the reduced capacity, it does not affect the use after parallel; when a lithium battery cell is shorted in parallel, the current in the parallel circuit is very large, which is usually avoided by fuse protection technology.

Disadvantages of lithium batteries in parallel and then in series

- ) Due to the difference in the internal resistance of the lithium battery cell and uneven heat dissipation, the cycle life of the lithium battery pack after paralleling will be affected.

The advantages of lithium batteries in series first and then in parallel

1. ) First connect in series according to the capacity of the lithium battery cell, such as 1/3 of the capacity of the entire group, and finally connect in parallel, which reduces the probability of failure of the large-capacity lithium battery module; first connect in series and then it is of great help to the consistency of the lithium battery pack.

2.) From the perspective of the reliability of the connection of the lithium battery pack, the development trend of voltage inconsistency and the impact of performance, the connection method in parallel and then in series is better than the connection method in series and then in parallel, and the topology of the lithium battery in series and then in parallel is conducive to the detection and management of each lithium battery cell in the system.

What’s The Difference Between Wiring Batteries in Series Vs. Parallel?

The main difference in wiring batteries in series vs. parallel is the impact on the output voltage and the capacity of the battery system. Batteries wired in series will have their voltages added together. Batteries wired in parallel will have their capacities (measured in amp-hours) added together. However, the total available energy (measured in watt-hours) in both configurations is the same.

For example, wiring two 12-volt batteries with 100 Ah capacities in series will output 24 volts with a 100 Ah capacity. Wiring the same two batteries in parallel will output 12 volts with a 200 Ah capacity. Thus, both systems have a total available energy of 240 watt-hours (watt-hours = volts x amp-hours).

Additionally, batteries wired in series and parallel configurations should all have the same voltage and capacity rating. Mixing and matching voltages and capacities can lead to problems that may damage your batteries.

Precautions for lithium batteries in series and parallel:

1.) Do not use different brands of batteries together.

2.) Do not use batteries of different voltages together.

3.) Do not mix different capacities or old and new lithium batteries together.

4.) Batteries of different chemical materials cannot be mixed, such as nickel-metal hydride and lithium batteries.

5.) When the battery is low, replace all the batteries.

6.) Use the lithium battery protection board with the corresponding parameters.

7.) Choose batteries with consistent performance. Generally, lithium batteries need to be paired with lithium battery cells for series and parallel use. Pairing standards: voltage difference ≤10mV, internal resistance difference ≤5mW, capacity difference ≤20mA

Warning & Instructions:

1.)Never ever short or touch the Positive (+) terminal of battery with Negative (-) terminal of battery to avoid short circuit, damage, injury, explosion or fire.

2.)Always connect the same voltage level and capacity of battery to avoid charging problems and shortened battery life.

3.)Don’t confuse (as it may be dangerous) with the complex wiring and connection of batteries in series-parallel. Always, do proper calculations and make schematic and diagrams of battery bank connections before implementing them in practical to be safe.

4.)Special care should be taken of polarity while charging the secondary batteries to avoid short circuit and hazardous condition.

5.)When battery gets fully charged, remove the charger to avoid overheating (In case of non automatic charger or charge controller).

6.)Always, charge battery at room temperature.

7.)Do not try to charge the primary cells. i.e. don’t charge the non-rechargeable batteries.

8.)Disconnect the battery from connected load if no longer in use to avoid corrosion and leakage.

9.)Disconnect the battery charging source and load before connecting or disconnecting terminals.

Precautions for ithium Battery

1.Lithium batteries must use a special charger, otherwise they may not reach the saturation state and affect their performance.

2.The lithium battery does not need to be fully discharged before charging.

3.Do not plug the charger into the socket for a long time, and remove the battery from the charger as soon as possible after it is fully charged.

4.The battery should be removed from electrical appliances that have not been used for a long time, and the battery should be emptied and stored.

5.Do not insert the positive and negative electrodes of the battery in reverse, otherwise it will cause the battery to bulge or breakNickel chargers and lithium chargers cannot be mixed.

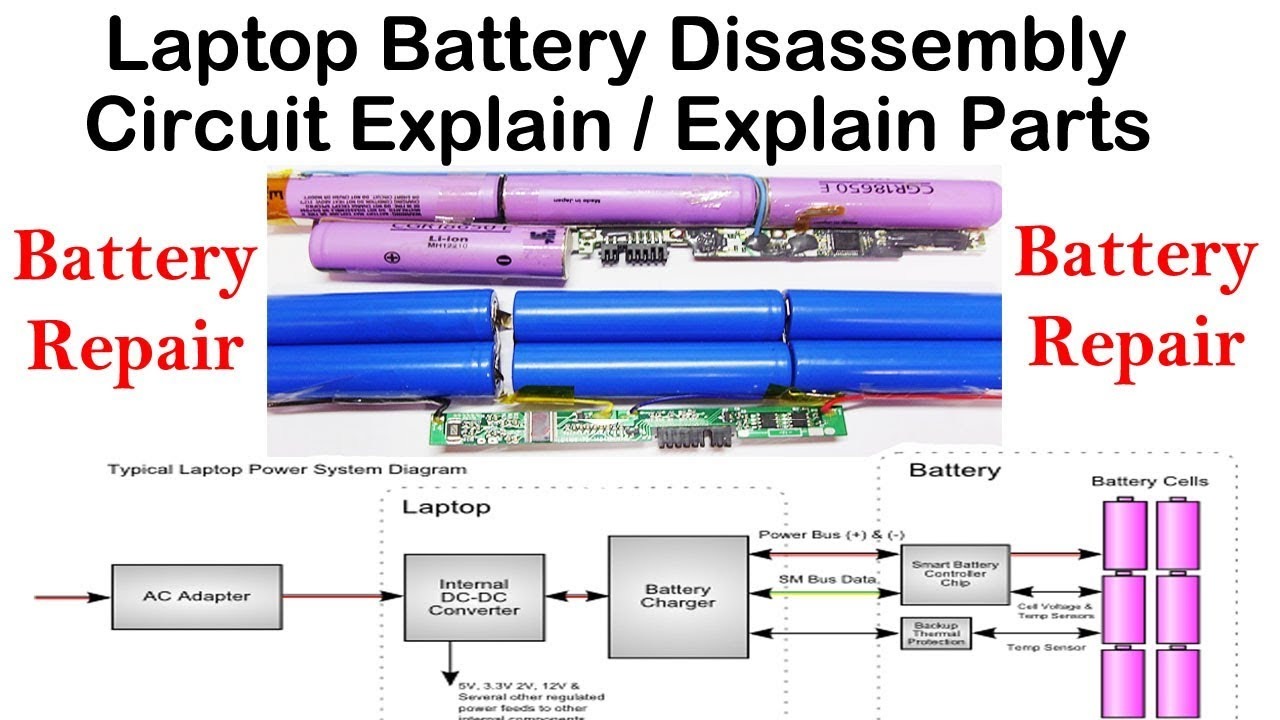

What is Lithium Battery PACK?

Lithium battery PACK refers to the processing, assembly and packaging of lithium battery packs. The process of assembling lithium batteries into groups is called PACK, which can be a single battery or a lithium battery pack in series and parallel. Lithium battery packs are usually composed of plastic housings, protective plates, batteries, output electrodes, connecting pads, and other insulating tape, double-sided tape, etc

Lithium cell: the core part of the finished battery

Protection board-BMS: It has functions such as overcharge, over discharge, overcurrent, short circuit, and intelligent protection of NTC temperature control.

Plastic shell: the supporting skeleton of the entire battery; positioning and fixing of the protective plate; carrying all other non-shell parts and limiting positions.

Terminal leads: Various terminal line charge and discharge interfaces can be provided for various electronic products, energy storage products, and backup power supplies.

Nickel sheet/bracket: connection and fixing components of battery cells